High-tech/optoelectronics: Professional turnkey services simplifying complexity

E&M System Planning

Our professional project team can provide comprehensive E&M engineering services for planning, design, and construction of integrated turnkey projects on various systems of clean room, HVAC, electrical, fire protection, air abatement system, factory monitoring and control system, supply and drainage system, process utility system, plant air system, ultra purified water system, waste water treatment system, gas system and chemical system. In view of the high quality standards and the limited time frame for construction of new manufacturing lab, the turnkey approach has become a normal practice. Contracting of turnkey E&M projects has inevitably become the norm. In view of the huge cost of plant construction in high-tech industries, it is a critical issue to simplify the complex, help project owners to reduce the coordination and integration required by subcontracting management, and conserve resources and ensure that plants can begin operation on time in spite of limited resources (budgetary and working period). We possess extensive turnkey project capabilities, and specialize in helping project owners implement plant construction plans, ensuring the owners' corporate resources are focused on their core operations, and meeting schedule requirements.

Integrated E&M Services

Basic Design

The members of our senior design team have more than 25 years of professional experience, and are familiar with the requirement of customers and industry. Thanks to the integration of our resources and technical knowledge, we can provide customers total design and build solution on E&M systems. We can also meet or the strictest industry requirements through use of all sets of new equipment and facilities meeting special specifications.

Our service scope now includes commercial and residential buildings, high rise buildings, microelectronics manufacturing fab and biotechnology plants. We can incorporate green architectural design concept and advanced energy conservation features in our basic designs, giving our customers buildings with the longest possible usable life and best possible cost effectiveness. We also are continuing to develop joint application on energy conservation, environmental protection, life support and green architecture.

Our basic, customized designs include the following systems:

- Power systems and generator

- Low voltage and telecommunications systems

- Water supply, drainage, and sanitation systems

- Fire protection systems

- HVAC systems and clean room interior systems

- Process cooling water systems

- Compressed air systems

- Process exhaust systems

- Special gas systems

- Purified water and process drainage systems

- Control and monitoring systems

Detailed Design

- Power systems and generator

- Low voltage and telecommunications systems

- Water supply, drainage, and sanitation systems

- Fire protection systems

- HVAC systems and clean room interior systems

- Process cooling water systems

- Compressed air systems

- Process exhaust systems

- Special gas systems

- Purified water and process drainage systems

- Control and monitoring systems

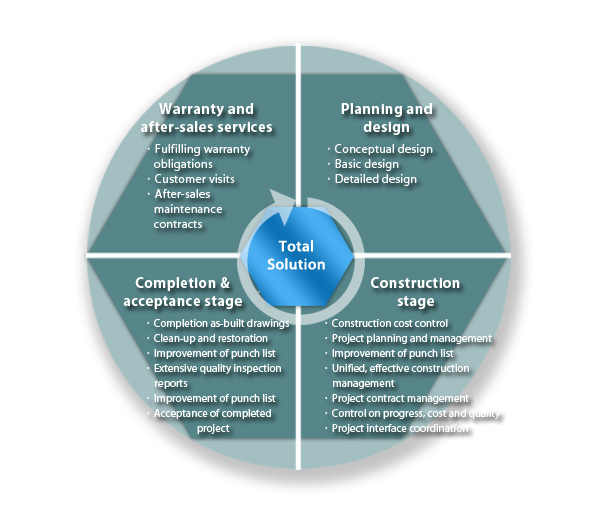

Turnkey Project Solution

KPEC's turnkey solutions provide customers with planning, design, construction, and maintenance services from a single source. With these services in mind, we can provide owners with feasibility assessment of different solutions and recommendations after assessing their plant construction budgets. We can help owners to effectively reach their plant construction goals within their budgets and time frames.

Our turnkey services encompass planning and implementation of all types of buildings and facilities, and we specialize in civil construction and E&M integration projects. We have actively solicited turnkey projects in recent years. Apart from costs down benefit for our customers, our turnkey solutions also ensure timely project completion and utilize the best possible technologies. In addition, we can enhance added value to customers by incorporating sustainable energy conservation systems.

We have passed ISO 9001 international quality management certification since 1999, and all our internal operations comply with ISO standards. We strictly control construction steps, including work safety control, quality management, procurement control, project progress and budget control, and on-site coordination.

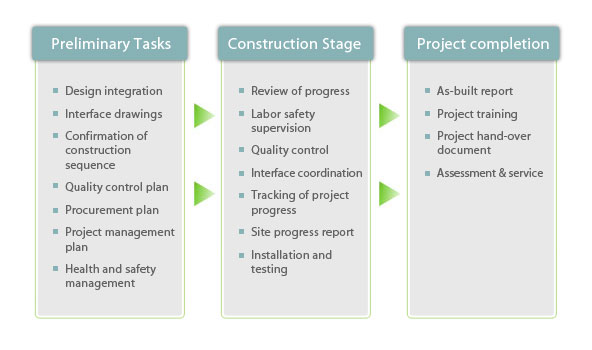

The following implementation outline lays out key tasks during turnkey project execution:

Commissioning, Hand-Over, Personnel Training and after-sale Services

It usually only takes several months from budget approval to completion of a high tech factory, which is followed by equipment move-in, testing, and preparation for production. The plant service life is at least 15 years or longer. Usually, there will be frequent changes to the plant's production layout during service life due to introduction of high-efficiency new equipment, more strict code and regulation, and tougher emission standards. As a consequence, the total cost of ownership over a plant's life cycle should be carefully considered when making the initial plant investment. In addition, total cost of ownership is closely related with the facility's commissioning, maintenance, and personnel training.

We possess a full range of professional testing personnel and precision measurement instruments. When materials and equipment are delivered to site for installation, we apply ISO standards to verify whether the items meet specifications and standards. When a project is completed, we perform testing/adjustment/balancing on the whole plant to ensure that the facility can operate smoothly. We offer routine system inspection and testing services; if we discover a potential problem, our professional team will immediately notify the customer and provide a feasible solution and a reasonable cost estimate, ensuring that the customer is able to easily maintain production and high efficiency.

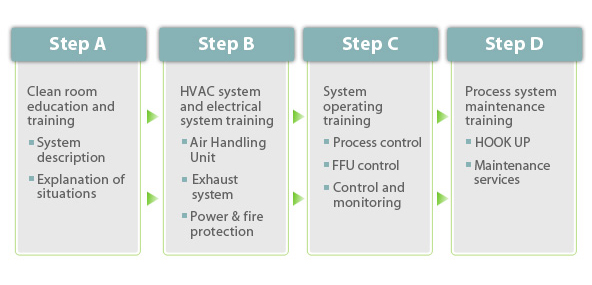

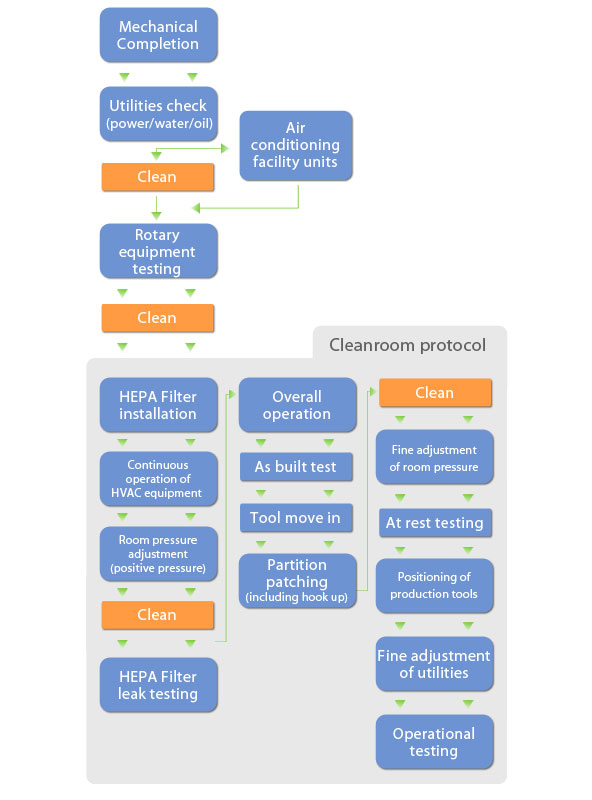

The following is part of a plant facility system operation process flowchart and an example education & training plan:

Clean room operation flowchart

Example training plan